| Sign In | Join Free | My chinacsw.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacsw.com |

|

Brand Name : AMC MACHINERY

Model Number : JH-1100PC

Certification : CE

Place of Origin : CHINA

MOQ : 1 set

Price : Negotiate

Payment Terms : T/T

Supply Ability : 5 sets per month

Delivery Time : 60 working days

Packaging Details : Corrugated box and plastic film

Voltage : 220V or 380V or 415V

Color : Customized

Max. sheet size : 1100x900mm

Min. sheet size : 130x70mm

Applicable paper : Cardboard: 250-800gsm, corrugated sheet F/E flute

Speed : 0-500m/min

High Speed Automatic Folder Gluer

Model: JH-1100PC

Features of JH series:

Specifications:

| Model | JH-1100PC |

| MAX. SHEET SIZE | 1100*900mm |

| MIN. SHEET SIZE | 130X70mm |

| APPLICABLE PAPER | cardboard:250g-800g, corrugated paper F, E |

| SPEED | 0-500M/min |

| MACHINE LENGTH | 16600mm |

| MACHINE WIDTH | 1800mm |

| MACHINE HEIGHT | 1450mm |

| TOAI POWER | 18.5KW |

| MAX.AIR DISPLACEMENT | 0.7m³/min |

| TOTAI WEIGHT | 6500kg |

Technical Parameters of Box Making:

| Basic type | Model | JH-1100PC | |

| Parameter | Max | Min | |

| 1.Straight line box

| A | 1050 | 160 |

| B | 900 | 75 | |

| C | 550 | 120 | |

| D | 100 | 10 | |

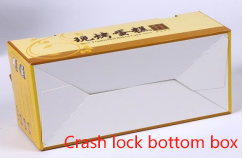

| 2.Crash lock bottom box

| A | 1000 | 260 |

| B | 550 | 75 | |

| C | 650 | 60 | |

| D | 150 | 25 | |

| E | 100 | 25 | |

| 3.Four corner box

| A | 1000 | 160 |

| B | 800 | 150 | |

| C | 650 | 220 | |

| D | 650 | 100 | |

| E | |||

| 4.Six corner box

| A | 1100 | 290 |

| B | 800 | 150 | |

| C | 650 | 120 | |

| D | 350 | 120 | |

| E | 50 | 30 | |

| 5.Box without cover | A | 1100 | 160 |

| B | 900 | 75 | |

| C | 550 | 120 | |

| D | 100 | 10 | |

Details of each section:

(1)FEEDER

·Independent motor driving system Synchronized feeding with main motor

Equipped with vibrating sheet separation system.

(2)PAPER REGULATING DEVICE

·Auto-correction of paper/sheets from the Feeder ensures feeding accuracy.

·Adjustable press drive ft for various thickness of paper/sheets.

(3)PRE-FOLDING

·Specific design ensures 180 degree on 1 st crease and 165 degree on 3rd crease.

4/6 back-hook system can be added as upgrade (optional).

(4)BOTTOM-FOLDING

·Equipped with bottom lock combination/adjustment, with ideally flexible design that ensures fast and easy operation.

·Sectional belt feeder with special design, flexible and adjustable per product requirement without tightening or loosening the belt.

·Electronic glue sprayer (required).

(5)FOLDING

·2nd crease 180 degree, 4th crease 180 degree.

·Specifically designed to adjust belt feeding speed separately to correct box embryo running direction and ensure straight feeding.

(6)TROMBONE (PRESSING)

·Auto-collecting of paper/sheets and water spray by photoelectric counter.

·Paper-jam inspection device.

·Adjustable upper and lower belts for easy and simple operation.

(7)CONVEYOR

·Movable stacking belts of 2 boards on left and right, adjustable on-line per stacking requirement to improve efficiency.

·Extra sponge belt for pressing of concave part the box piles.

·Air-pressed easy adjustment to ensure even pressure of gluing.

·Synchronized in proportion with main motor in automatic mode to improve stable stacking.

Box display:

|

|

Custom 18.5KW Folder Gluer Machine High Speed Full Automatic JH-1100PC Images |